In the field of metal forging, steel and aluminum alloy are the two most commonly used materials, each with unique performance characteristics and applicable scenarios. This article will systematically analyze the advantages and disadvantages of forged steel and forged aluminum from three aspects: material properties, process characteristics and application fields.

1. Comparison of material properties

Forged steel has significant advantages in mechanical properties. After proper heat treatment, the strength of forged steel can reach more than 1000MPa, and some high-strength alloy steels can even reach 2000MPa. This excellent strength property enables forged steel parts to withstand extremely high loads and impacts, and is particularly suitable for harsh working conditions such as heavy machinery and mining equipment. In addition, steel has excellent high temperature resistance and can still maintain good mechanical properties in a high temperature environment of 400-500℃, which is unmatched by aluminum alloys. The fatigue life of steel is also significantly better than that of aluminum alloys, and it shows a longer service life under alternating loads.

In contrast, the most prominent advantage of forged aluminum is its lightweight characteristics. The density of aluminum alloy is only 2.7g/cm³, which is about one-third of that of steel. This property is of decisive significance in weight-sensitive fields such as aerospace and automobile manufacturing. After forging and heat treatment, modern high-strength aluminum alloys such as 7075-T6 can reach a tensile strength of more than 500MPa. Although the absolute value is lower than that of steel, its specific strength (ratio of strength to density) is better than most steel. Aluminum alloys also have good corrosion resistance. The oxide film naturally formed on the surface can effectively resist atmospheric corrosion, reducing the need for protective treatment.

2. Differences in process characteristics

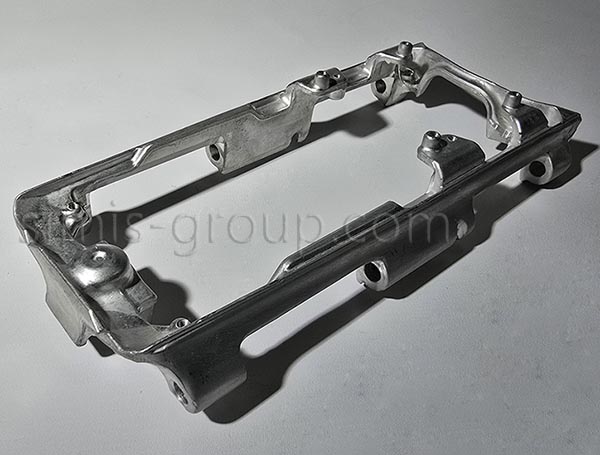

In terms of forging technology, aluminum alloys show obvious processing advantages. The forging temperature of aluminum is usually in the range of 350-500℃, which is much lower than the 1000-1200℃ of steel, which not only reduces energy consumption but also prolongs the service life of the mold. The deformation resistance of aluminum is small, making the forging process easier to control and enabling more complex shapes and finer features. In addition, aluminum alloy forgings usually do not require subsequent heat treatment to obtain better comprehensive performance, simplifying the production process.

Although steel forging has high temperature requirements, it has unique advantages in microstructure control. Through controlled forging and controlled cooling technology, the grain size and phase composition of steel can be precisely controlled to obtain an ideal combination of strength and toughness. The forging temperature window of steel is wide, and the process adjustment space is large, which is suitable for the production of oversized forgings. However, steel forgings usually require heat treatment such as quenching + tempering to achieve optimal performance, which increases the production cycle and cost.

3. Application field selection

In actual applications, forged steel parts mainly occupy the market in high-load and high-temperature environments. Key load-bearing components of heavy machinery such as crankshafts, connecting rods, gears, etc. are preferred to forged steel. Large rotors in energy equipment, nuclear power pressure vessels and other components with extremely high reliability and life requirements are forged steel. Special components such as armor plates and gun barrels in the military industry also rely on the special properties of steel.

Forged aluminum parts shine in areas where lightweight demand is prominent. Aluminum forgings account for more than 60% of the structural parts of modern passenger aircraft, including key components such as fuselage frames and landing gear. New energy vehicles can reduce weight by 30-40% by using aluminum forged suspension components, significantly improving the driving range. Heat dissipation components in electronic products also use a large number of forged aluminum alloys to take advantage of their excellent thermal conductivity. In addition, aluminum forgings are also widely used in sports equipment, medical equipment and other fields.

4. Economic and sustainable development

From the perspective of the whole life cycle cost, forged aluminum has unique advantages. Although the price of raw materials is higher than that of steel, the energy savings brought by lightweight use can usually recover the cost difference within 1-2 years. Aluminum alloys are extremely recyclable, and the energy consumption of recycled aluminum is only 5% of that of original aluminum, which meets the requirements of the circular economy. Although steel has an advantage in initial material costs, hidden costs such as anti-corrosion treatment and additional energy consumption caused by weight need to be considered.

5. Future development trends

In terms of material innovation, the research and development of high-strength aluminum alloys and ultra-high-strength steels are continuing to advance. New materials such as aluminum-lithium alloys and nanocrystalline aluminum alloys are expected to further improve the performance of forged aluminum. In terms of process innovation, advanced technologies such as isothermal forging and multi-directional forging are breaking through traditional limitations. The application of intelligent forging systems will improve the quality stability of steel and aluminum forgings at the same time.

In summary, forged steel and forged aluminum have their own advantages, and the choice should be made by comprehensively considering load conditions, weight requirements, environmental factors and cost constraints. In the future, the two will not simply replace each other, but will develop in synergy in their respective areas of strength and jointly promote technological progress in the manufacturing industry.